最近一直在写关于计算机编程和日语的东西,都差点忘记了我是一名机械工程师。那就浅薄地分享一些我对机械螺纹的看法和资料,如有错漏,还望不吝赐教,谢谢!

前言

螺纹一般分为机械螺纹和自攻螺纹,后者无需螺母,可以直接固定两个部件,但通常机械行业较少使用。故就来简单讲讲我对机械螺纹的理解。

其实我称之为机械螺纹的国标官方称呼是 “机牙螺纹”,但是因为大部分输入法输入这几个字的时候一般不在候选列表内,另外日本和台湾地区管这个叫机械螺纹,我也就习惯性地也称呼为机械螺纹了,希望各位不要介意。

公制螺纹 (M)

在国内,用的最多的是公制螺纹,即 Mn×P(n 为螺纹公称直径,P 为螺距,粗牙可省略)。牙型脚为 60°。日本、台湾和欧洲大陆地区也很常用这个公制螺纹。

| 规格 | 螺距 P | 大径 MAX | 大径 MIN | 底径 MAX | 底径 MIN |

|---|---|---|---|---|---|

| M1 | 0.25 | 0.98 | 0.838 | 0.729 | 0.693 |

| M1.1 | 0.25 | 1.098 | 0.938 | 0.829 | 0.793 |

| M1.2 | 0.25 | 1.18 | 1.14 | 1.04 | 1.01 |

| M1.4 | 0.3 | 1.38 | 1.34 | 1.2 | 1.16 |

| M1.7 | 0.35 | 1.68 | 1.61 | 1.46 | 1.42 |

| M2 | 0.4 | 1.98 | 1.89 | 1.72 | 1.69 |

| M2.3 | 0.4 | 2.28 | 2.19 | 2.02 | 1.99 |

| M2.5 | 0.45 | 2.48 | 2.38 | 2.18 | 2.15 |

| M2.6 | 0.45 | 2.58 | 2.48 | 2.28 | 2.25 |

| M3 | 0.5 | 2.98 | 2.88 | 2.64 | 2.61 |

| M3.5 | 0.6 | 3.47 | 3.36 | 3.06 | 3.03 |

| M4 | 0.7 | 3.98 | 3.84 | 3.49 | 3.15 |

| M4.5 | 0.75 | 4.47 | 4.34 | 3.96 | 3.92 |

| M5 | 0.8 | 4.98 | 4.83 | 4.43 | 4.38 |

| M6 | 1 | 5.97 | 5.82 | 5.3 | 5.25 |

| M7 | 1 | 6.97 | 6.82 | 6.3 | 6.25 |

| M8 | 1.25 | 7.96 | 7.79 | 7.12 | 7.07 |

| M9 | 1.25 | 8.96 | 8.79 | 8.12 | 8.07 |

| M10 | 1.5 | 9.96 | 9.77 | 8.97 | 8.91 |

| M11 | 1.5 | 10.97 | 10.73 | 9.97 | 9.91 |

| M12 | 1.75 | 11.95 | 11.76 | 10.79 | 10.73 |

| M14 | 2 | 13.95 | 13.74 | 12.63 | 12.56 |

| M16 | 2 | 15.95 | 15.74 | 14.63 | 14.56 |

| M18 | 2.5 | 17.95 | 17.71 | 16.31 | 16.23 |

| M20 | 2.5 | 19.95 | 19.71 | 18.31 | 18.23 |

| M22 | 2.5 | 21.95 | 21.71 | 20.31 | 20.23 |

| M24 | 3 | 23.94 | 23.68 | 21.98 | 21.9 |

| M27 | 3 | 26.94 | 26.68 | 24.98 | 24.89 |

| M30 | 3.5 | 29.94 | 29.66 | 27.66 | 27.56 |

| M33 | 3.5 | 32.94 | 32.66 | 30.65 | 30.56 |

| M36 | 4 | 35.93 | 35.63 | 33.33 | 33.23 |

| 规格 | 螺距 P | 大径 MAX | 大径 MIN | 底径 MAX | 底径 MIN |

|---|---|---|---|---|---|

| M1.4 | 0.2 | 1.4 | 1.344 | 1.27 | 1.22 |

| M1.6 | 0.2 | 1.583 | 1.527 | 1.45 | 1.4 |

| M1.8 | 0.2 | 1.783 | 1.727 | 1.65 | 1.6 |

| M2.0 | 0.25 | 1.982 | 1.915 | 1.82 | 1.76 |

| M2.2 | 0.25 | 2.182 | 2.115 | 2.02 | 1.96 |

| M2.5 | 0.35 | 2.481 | 2.396 | 2.25 | 2.19 |

| M3.0 | 0.35 | 2.981 | 2.896 | 2.75 | 2.68 |

| M3.5 | 0.35 | 3.481 | 3.396 | 3.25 | 3.18 |

| M4 | 0.5 | 3.98 | 3.874 | 3.61 | 3.57 |

| M4.5 | 0.5 | 4.48 | 4.374 | 4.11 | 4.07 |

| M5 | 0.5 | 4.98 | 4.874 | 4.61 | 4.57 |

| M6 | 0.75 | 5.978 | 5.838 | 5.45 | 5.41 |

| M7 | 0.75 | 6.978 | 6.838 | 6.45 | 6.41 |

| M8 | 1 | 7.974 | 7.794 | 7.29 | 7.24 |

| M9 | 1 | 8.974 | 8.794 | 8.29 | 8.24 |

| M10 | 1.25 | 9.972 | 9.76 | 9.12 | 9.07 |

| M10 | 1 | 9.974 | 9.794 | 9.28 | 9.23 |

| M12 | 1.25 | 11.972 | 11.76 | 11.12 | 11.07 |

| M12 | 1.5 | 11.968 | 11.732 | 10.95 | 10.89 |

| M14 | 1.5 | 13.968 | 13.732 | 12.95 | 12.89 |

| M16 | 1.5 | 15.968 | 15.732 | 14.95 | 14.89 |

| M18 | 2 | 17.962 | 17.682 | 16.62 | 16.54 |

| M18 | 1.5 | 17.968 | 17.732 | 16.93 | 16.86 |

| M20 | 2 | 19.962 | 19.682 | 18.62 | 18.54 |

| M20 | 1.5 | 19.968 | 19.732 | 18.92 | 18.85 |

| M22 | 1.5 | 21.968 | 21.732 | 20.92 | 20.85 |

| M24 | 1.5 | 23.968 | 23.732 | 22.92 | 22.85 |

| M26 | 1.5 | 25.968 | 25.732 | 24.93 | 24.85 |

| M27 | 1.5 | 26.968 | 26.732 | 25.93 | 25.85 |

| M28 | 1.5 | 27.968 | 27.732 | 26.93 | 26.85 |

| M30 | 1.5 | 29.968 | 29.732 | 28.93 | 28.85 |

| M32 | 1.5 | 31.968 | 31.732 | 30.93 | 30.85 |

| M33 | 1.5 | 32.968 | 32.732 | 31.93 | 31.85 |

管螺纹 (G R Rc Rp NPT)

这是一个深坑,分为好多标准,建议参阅 Rc1/8,G3/4,NPT1/4 的含义是什么?BSPT,NPT,Rc,G 等螺纹又有什区别?,我就列几个常用的吧。

英制 55° 非密封管螺纹,一般代号为 G,这是国内最常用的英制螺纹,通常配合生料带或密封圈用在流体管道连接。

行业黑话:1/8 代表 1 分,1/4 代表 2 分,以此类推。

| 尺寸代号 | 每 25.4㎜内所包含的牙数 | 螺距 | 牙高 | 大径 (基准直径) | 中径 | 小径 |

|---|---|---|---|---|---|---|

| 1/16 | 27 | 0.941 | 0.752 | 7.894 | 7.142 | 6.389 |

| 1/8 | 27 | 0.941 | 0.752 | 10.242 | 9.489 | 8.737 |

| 1/4 | 18 | 1.411 | 1.129 | 13.616 | 12.487 | 11.358 |

| 3/8 | 18 | 1.411 | 1.129 | 17.055 | 15.926 | 14.797 |

| 1/2 | 14 | 1.814 | 1.451 | 21.224 | 19.772 | 18.321 |

| 3/4 | 14 | 1.814 | 1.451 | 26.569 | 25.117 | 23.666 |

| 1 | 11.5 | 2.209 | 1.767 | 33.228 | 31.461 | 29.694 |

| 1¼ | 11.5 | 2.209 | 1.767 | 41.985 | 40.218 | 38.451 |

| 1½ | 11.5 | 2.209 | 1.767 | 48.054 | 46.287 | 44.52 |

| 2 | 11.5 | 2.209 | 1.767 | 60.092 | 58.325 | 56.558 |

| 2½ | 8 | 3.175 | 2.54 | 72.699 | 70.159 | 67.619 |

| 3 | 8 | 3.175 | 2.54 | 88.608 | 86.068 | 83.528 |

| 3½ | 8 | 3.175 | 2.54 | 101.316 | 98.776 | 96.236 |

| 4 | 8 | 3.175 | 2.54 | 113.973 | 111.433 | 108.893 |

| 5 | 8 | 3.175 | 2.54 | 140.952 | 138.412 | 135.872 |

| 6 | 8 | 3.175 | 2.54 | 167.792 | 165.252 | 162.712 |

| 8 | 8 | 3.175 | 2.54 | 218.441 | 215.901 | 213.361 |

| 10 | 8 | 3.175 | 2.54 | 272.312 | 269.772 | 267.232 |

| 12 | 8 | 3.175 | 2.54 | 323.032 | 320.492 | 317.952 |

英制 55° 密封管螺纹,R 为外锥管螺纹,Rc 为内锥管螺纹,Rp 为内柱管螺纹。

R 可以和 Rc、Rp、G 配合;Rc 和 Rp 只能和 R 配合。

| 尺寸代号 | 每 25.4㎜内所包含的牙数 | 螺距 | 牙高 | 大径 (基准直径) | 中径 | 小径 |

|---|---|---|---|---|---|---|

| 1/16 | 28 | 0.907 | 0.581 | 7.723 | 7.142 | 6.561 |

| 1/8 | 28 | 0.907 | 0.581 | 9.728 | 9.147 | 8.566 |

| 1/4 | 19 | 1.337 | 0.856 | 13.157 | 12.301 | 11.445 |

| 3/8 | 19 | 1.337 | 0.856 | 16.662 | 15.806 | 14.95 |

| 1/2 | 14 | 1.814 | 1.162 | 20.955 | 19.793 | 18.631 |

| 3/4 | 14 | 1.814 | 1.162 | 26.441 | 25.279 | 24.117 |

| 1 | 11 | 2.309 | 1.479 | 33.249 | 31.77 | 30.291 |

| 1¼ | 11 | 2.309 | 1.479 | 41.91 | 40.431 | 38.952 |

| 1½ | 11 | 2.309 | 1.479 | 47.803 | 46.324 | 44.845 |

| 2 | 11 | 2.309 | 1.479 | 59.614 | 58.135 | 56.656 |

| 2½ | 11 | 2.309 | 1.479 | 75.184 | 73.705 | 72.226 |

| 3 | 11 | 2.309 | 1.479 | 87.884 | 86.405 | 84.926 |

| 4 | 11 | 2.309 | 1.479 | 113.03 | 111.551 | 110.072 |

| 5 | 11 | 2.309 | 1.479 | 138.43 | 136.951 | 135.472 |

| 6 | 11 | 2.309 | 1.479 | 163.83 | 162.351 | 160.872 |

美制 60° 密封管螺纹,内外螺纹均为锥型,这个一般不常用。

| 尺寸代号 | 每 25.4㎜内所包含的牙数 | 螺距 | 牙高 | 大径 (基准直径) | 中径 | 小径 |

|---|---|---|---|---|---|---|

| 1/16 | 27 | 0.941 | 0.752 | 7.894 | 7.142 | 6.389 |

| 1/8 | 27 | 0.941 | 0.752 | 10.242 | 9.489 | 8.737 |

| 1/4 | 18 | 1.411 | 1.129 | 13.616 | 12.487 | 11.358 |

| 3/8 | 18 | 1.411 | 1.129 | 17.055 | 15.926 | 14.797 |

| 1/2 | 14 | 1.814 | 1.451 | 21.224 | 19.772 | 18.321 |

| 3/4 | 14 | 1.814 | 1.451 | 26.569 | 25.117 | 23.666 |

| 1 | 11.5 | 2.209 | 1.767 | 33.228 | 31.461 | 29.694 |

| 1¼ | 11.5 | 2.209 | 1.767 | 41.985 | 40.218 | 38.451 |

| 1½ | 11.5 | 2.209 | 1.767 | 48.054 | 46.287 | 44.52 |

| 2 | 11.5 | 2.209 | 1.767 | 60.092 | 58.325 | 56.558 |

| 2½ | 8 | 3.175 | 2.54 | 72.699 | 70.159 | 67.619 |

| 3 | 8 | 3.175 | 2.54 | 88.608 | 86.068 | 83.528 |

| 3½ | 8 | 3.175 | 2.54 | 101.316 | 98.776 | 96.236 |

| 4 | 8 | 3.175 | 2.54 | 113.973 | 111.433 | 108.893 |

| 5 | 8 | 3.175 | 2.54 | 140.952 | 138.412 | 135.872 |

| 6 | 8 | 3.175 | 2.54 | 167.792 | 165.252 | 162.712 |

| 8 | 8 | 3.175 | 2.54 | 218.441 | 215.901 | 213.361 |

| 10 | 8 | 3.175 | 2.54 | 272.312 | 269.772 | 267.232 |

| 12 | 8 | 3.175 | 2.54 | 323.032 | 320.492 | 317.952 |

英制螺纹 (BSW BA)

| 规格 | 牙数 | 大径 MAX | 大径 MIN | 底径 MAX | 底径 MIN |

|---|---|---|---|---|---|

| 1/16 | 60 | 1.56 | 1.47 | 1.29 | 1.27 |

| 3/32 | 48 | 2.361 | 2.155 | 2.01 | 1.99 |

| 1/8 | 40 | 3.155 | 3.045 | 2.72 | 2.7 |

| 5/32 | 32 | 3.945 | 3.795 | 3.4 | 3.38 |

| 3/16 | 24 | 4.742 | 4.592 | 4.03 | 4 |

| 1/4 | 20 | 6.33 | 6.16 | 5.48 | 5.45 |

| 5/16 | 18 | 7.91 | 7.72 | 6.97 | 6.94 |

| 3/8 | 16 | 9.5 | 9.31 | 8.44 | 8.4 |

| 7/16 | 14 | 11.082 | 10.892 | 9.88 | 9.84 |

| 1/2 | 12 | 12.67 | 12.46 | 11.27 | 11.22 |

| 9/16 | 12 | 14.258 | 14.047 | 12.86 | 12.81 |

| 5/8 | 11 | 15.848 | 15.605 | 14.33 | 14.27 |

| 3/4 | 10 | 19.02 | 18.78 | 17.34 | 17.28 |

| 7/8 | 9 | 22.195 | 21.935 | 20.32 | 20.28 |

| 1” | 8 | 25.37 | 25.11 | 23.27 | 23.23 |

| 1⅛ | 7 | 28.575 | 26.251 | 23.93 | 24.75 |

| 1¼ | 7 | 31.75 | 29.426 | 27.11 | 27.25 |

| 1½ | 6 | 38.1 | 35.39 | 32.68 | 33.5 |

| 规格 | 牙数 | 大径 MAX | 大径 MIN | 底径 MAX | 底径 MIN |

|---|---|---|---|---|---|

| 0BA | 1 | 5.97 | 5.82 | 5.32 | 5.22 |

| 1BA | 0.9 | 5.27 | 5.12 | 4.685 | 4.58 |

| 2BA | 0.81 | 4.676 | 4.526 | 4.15 | 4.016 |

| 3BA | 0.73 | 4.078 | 3.938 | 3.604 | 3.479 |

| 4BA | 0.66 | 3.57 | 3.46 | 3.141 | 3.045 |

| 5BA | 0.59 | 3.18 | 3.05 | 2.797 | 2.779 |

| 6BA | 0.53 | 2.78 | 2.66 | 2.436 | 2.327 |

| 7BA | 0.48 | 2.47 | 2.38 | 2.2 | 2.18 |

| 8BA | 0.43 | 1.81 | 1.72 | 1.531 | 1.45 |

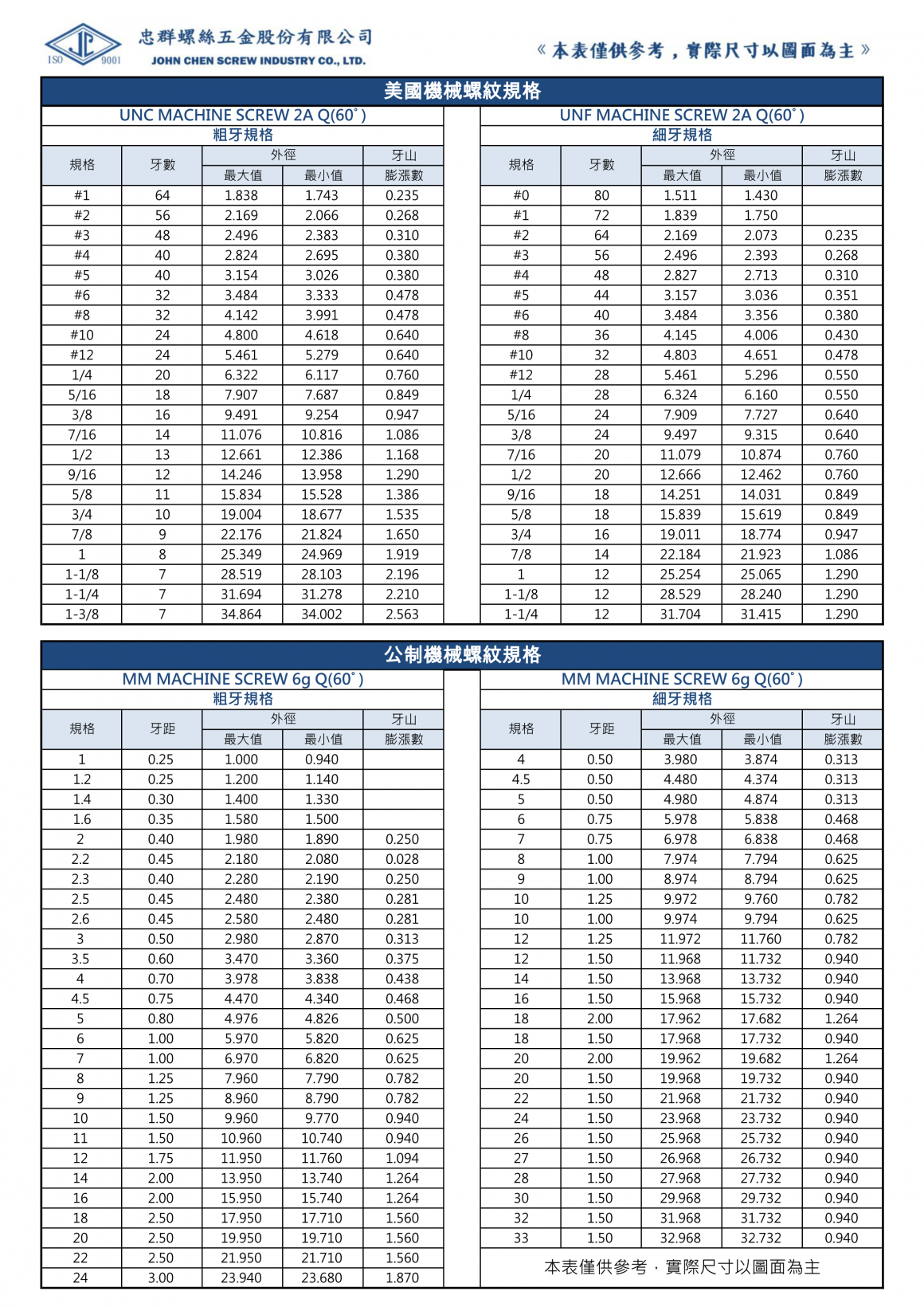

美制螺纹 (UNC NUF)

| 规格 | 牙数 | 大径 MAX | 大径 MIN | 底径 MAX | 底径 MIN |

|---|---|---|---|---|---|

| #1 | 64 | 1.838 | 1.743 | 1.57 | 1.54 |

| #2 | 56 | 2.169 | 2.066 | 1.86 | 1.84 |

| #3 | 48 | 2.496 | 2.383 | 2.14 | 2.11 |

| #4 | 40 | 2.824 | 2.695 | 2.4 | 2.36 |

| #5 | 40 | 3.154 | 3.026 | 2.72 | 2.69 |

| #6 | 32 | 3.484 | 3.333 | 2.95 | 2.91 |

| #8 | 32 | 4.142 | 3.991 | 3.6 | 3.57 |

| #10 | 24 | 4.8 | 4.618 | 4.09 | 4.05 |

| #12 | 24 | 5.461 | 5.279 | 4.75 | 4.7 |

| 1/4 | 20 | 6.322 | 6.117 | 5.5 | 5.45 |

| 5/16 | 18 | 7.907 | 7.687 | 6.98 | 6.93 |

| 3/8 | 16 | 9.491 | 9.254 | 8.45 | 8.4 |

| 7/16 | 14 | 11.076 | 10.816 | 9.89 | 9.83 |

| 1/2 | 13 | 12.661 | 12.386 | 11.39 | 11.32 |

| 9/16 | 12 | 14.246 | 13.958 | 12.87 | 12.8 |

| 5/8 | 11 | 15.834 | 15.528 | 14.33 | 14.26 |

| 3/4 | 10 | 19.004 | 18.677 | 17.34 | 17.27 |

| 7/8 | 9 | 22.176 | 21.824 | 20.34 | 20.26 |

| 1” | 8 | 25.349 | 24.969 | 23.28 | 23.2 |

| 1⅛ | 7 | 28.519 | 28.103 | 26.16 | 26.07 |

| 1¼ | 7 | 31.694 | 31.278 | 29.33 | 29.24 |

| 1⅜ | 7 | 34.864 | 34.002 | 32.12 | 32.02 |

| 1½ | 6 | 38.039 | 37.577 | 35.29 | 35.08 |

| 1¾ | 5 | 44.381 | 43.861 | 4108 | 40.86 |

| 规格 | 牙数 | 大径 MAX | 大径 MIN | 底径 MAX | 底径 MIN |

|---|---|---|---|---|---|

| #0 | 80 | 1.511 | 1.431 | 1.31 | 1.26 |

| #1 | 72 | 1.838 | 1.751 | 1.61 | 1.56 |

| #2 | 64 | 2.169 | 2.073 | 1.91 | 1.89 |

| #3 | 56 | 2.496 | 2.393 | 2.2 | 2.17 |

| #4 | 48 | 2.827 | 2.713 | 2.47 | 2.44 |

| #5 | 44 | 3.157 | 3.036 | 2.76 | 2.73 |

| #6 | 40 | 3.484 | 3.356 | 3.05 | 3.02 |

| #8 | 36 | 4.145 | 4.006 | 3.66 | 3.63 |

| #10 | 32 | 4.803 | 4.651 | 4.26 | 4.23 |

| #12 | 28 | 5.461 | 5.296 | 4.85 | 4.81 |

| 1/4 | 28 | 6.324 | 6.16 | 5.72 | 5.68 |

| 5/16 | 24 | 7.909 | 7.727 | 7.2 | 7.16 |

| 3/8 | 24 | 9.497 | 9.315 | 8.76 | 8.74 |

| 7/16 | 20 | 11.079 | 10.874 | 10.23 | 10.18 |

| 1/2 | 20 | 12.666 | 12.462 | 11.82 | 11.76 |

| 9/16 | 18 | 14.251 | 14.031 | 13.31 | 13.25 |

| 5/8 | 18 | 15.839 | 15.619 | 14.89 | 14.83 |

| 3/4 | 16 | 19.011 | 18.774 | 17.95 | 17.89 |

| 7/8 | 14 | 22.184 | 21.923 | 20.98 | 20.91 |

| 1” | 12 | 25.254 | 25.065 | 23.95 | 23.87 |

| 1⅛ | 12 | 28.529 | 28.24 | 27.12 | 27.05 |

| 1¼ | 12 | 31.704 | 31.415 | 30.29 | 30.21 |

| 1⅜ | 12 | 34.876 | 34.588 | 33.46 | 33.38 |

| 1½ | 12 | 38.051 | 37.763 | 36.63 | 36.55 |

螺丝头型

通常外六角、圆柱头、圆锥头和盘头(半圆头)用得最多,下面出自螺丝头型对照表

螺丝槽型

一般用的最多是一字、十字、内六角和梅花槽型。下面转自槽型對照表。

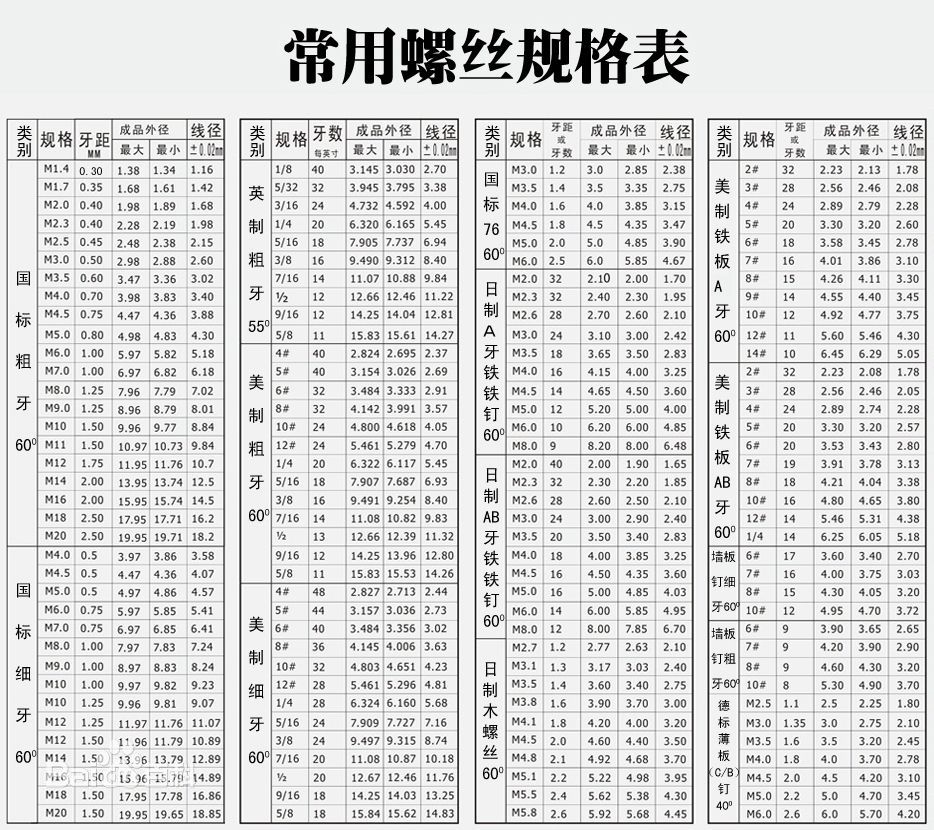

常用资料

转自互联网,如有侵权,请提供版权信息联系 [email protected],将在第一时间删除,谢谢!